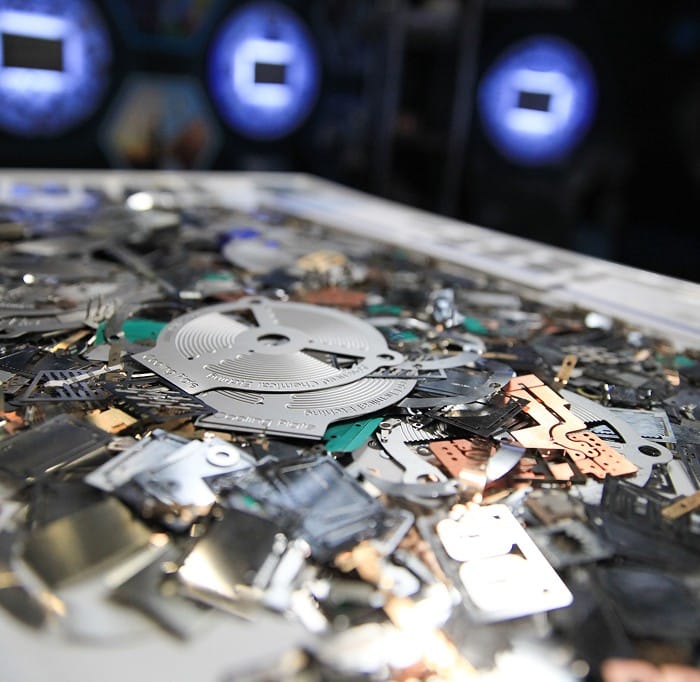

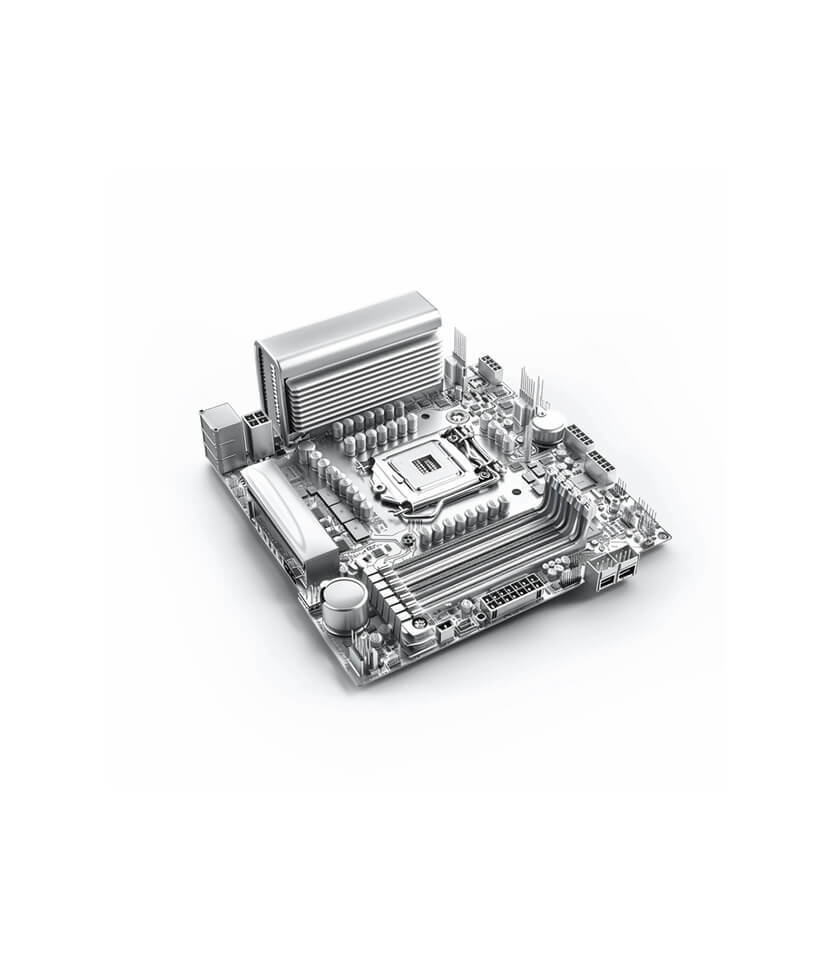

Whether the component is a micro connector for a mobile phone or a large screening can for a base station, ACE plays a significant role in connecting the world. We can handle micro-sized parts in microelectronics to heavy-duty lead frames and busbars.

Our fast turnaround, speed of response, and proven manufacturing track record make us a perfect partner for engineers working in a sector where the demand for everchanging and evolving products is relentless.

More Complexity, Same Price

Part cost does not increase with complexity, which allows designers to ask for more complex designs to achieve their design targets.

Low-Risk Product Development

Thanks to CAD tooling, the photo etching process is low-risk for product development. Customers get their new designs to market quicker than their competitors. Once the prototype design has been approved moving to higher volumes is easy.

ACE supply thousands of screening cans in various metals. We offer stainless steel etching, copper etching, nickel alloys and aluminium etching.

Screening cans can be produced either formed or flat with half etched fold lines for hand forming by the customer. Screens can also be supplied with selective electrical insulation coating on either flat or formed parts.

ACE supply many types of busbars and heavy gauge lead frames, up to 2mm thick and usually in copper or aluminium. The photo etching process has the capability to etch steps in the metal to place electronic components, whilst busbars can be 3D formed and then plated either all over or selective.

ACE supply millions of etched lead frame strips quickly, in either copper or nickel alloys. We also supply millions of cooling plates with complex etched channel designs for semi-conductor customers in various metals. We do this through processes such as stainless steel etching, nickel alloy etching and titanium etching.

ACE offers a wide range of in-house processes, including forming (hard form and forming using fold lines), spot welding, machining and assembly.