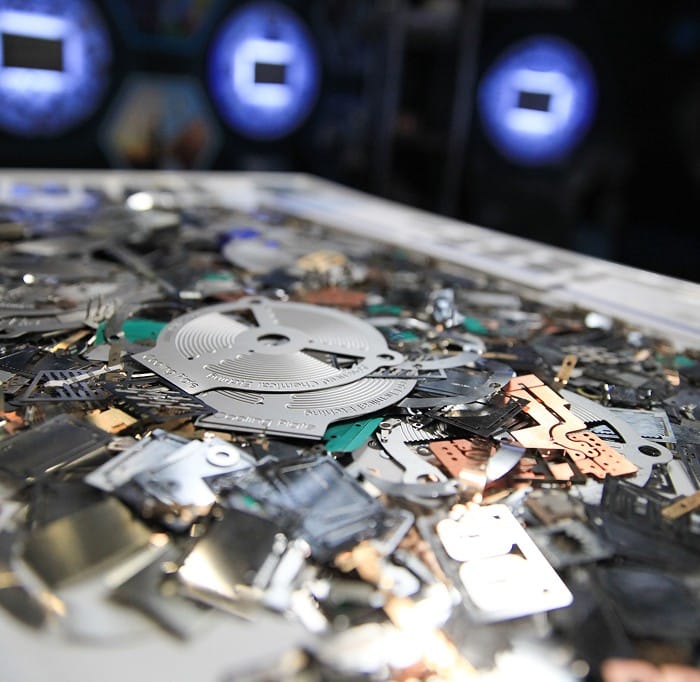

ACE, one of the largest specialist metal component manufacturers in Europe, is innovating and developing a number of manufacturing processes to meet the needs of EV (Electric Vehicle) systems.

Typical components for this application include bus bars from Copper or Aluminium, cooling and heat exchanger plates, manufactured using a unique chemical etching process within ACE’s state-of-the-art facility in Telford.

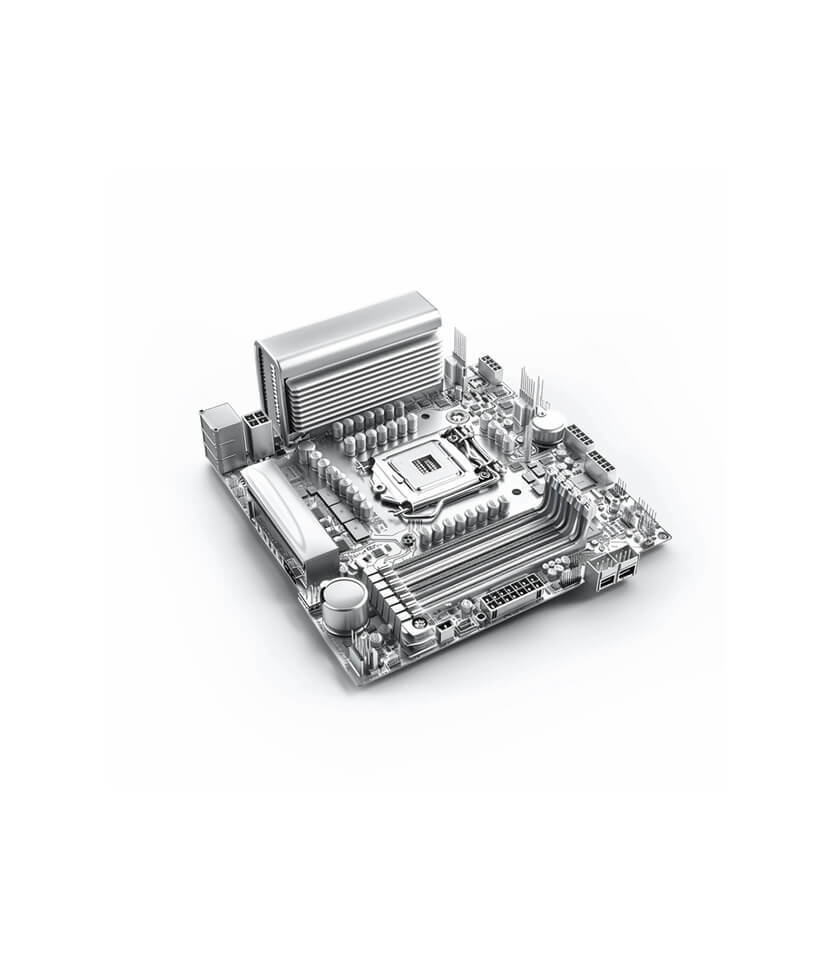

Driving EV Forward

ACE’s focus on bringing innovation and evolution to the electric vehicle sector is driving the development of the next generation of EV vehicles.

Developing The Future

Our strong focus on the development of ever more accurate chemical etching techniques means that ACE remains at the forefront of EV components manufacturing capability and capacity.