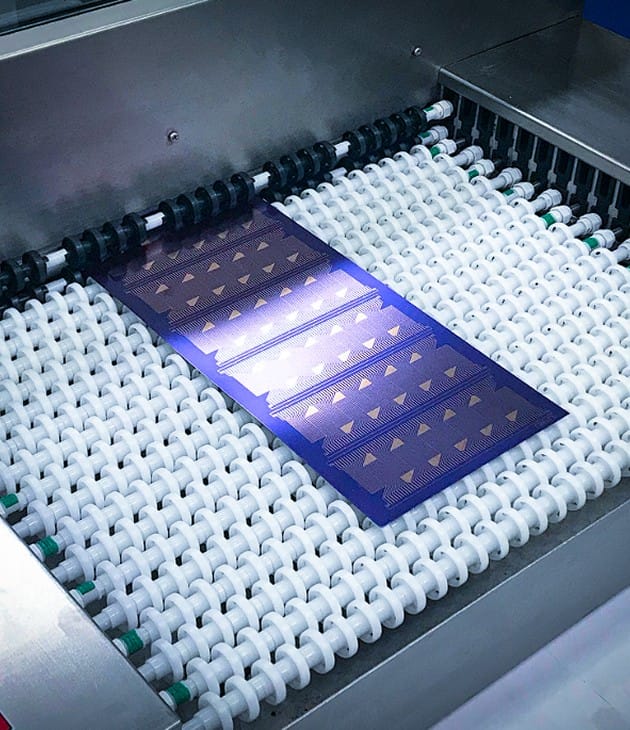

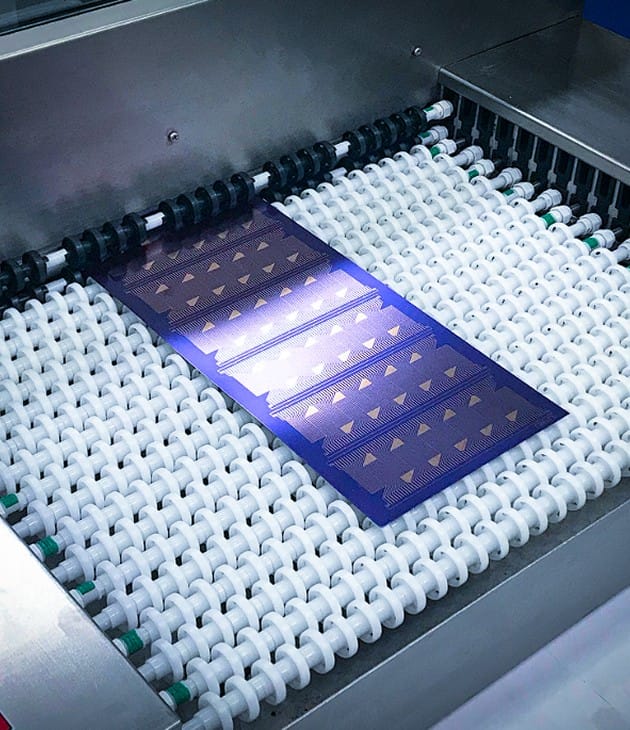

Chemical etching is the process of using corrosive chemicals to remove metal locally from a sheet, leaving the shape of the desired component behind. Find out more about the chemical etching process.

Chemical etching is a machining process that utilises chemicals to produce intricate components from a wide range of materials. This is done with a corrosive chemical (etchant), which is normally some form of acid and is used to dissolve unwanted material away to produce the final design. Our preferred etchant is Ferric Chloride (FeCI3). Unlike other machining processes, the components produced by precision chemical etching are stress-free with no burrs or rough edges and with no changes to the original material properties.

Highly Accurate Manufacturing

Chemical etching is a manufacturing method for producing highly complex and accurate metal components in most metals including aluminium, copper alloys, nickel alloys, titanium alloys and other exotic metals, between 0.005mm to 2.5mm thick.

More Complexity, Same Price

Many customers select chemical etching because of the flexibility it provides for supplying samples in days rather than weeks or months. The complexity of the profile does not affect the price… to process thousands of apertures or just the one, the price remains the same.

Minimum Feature Sizes

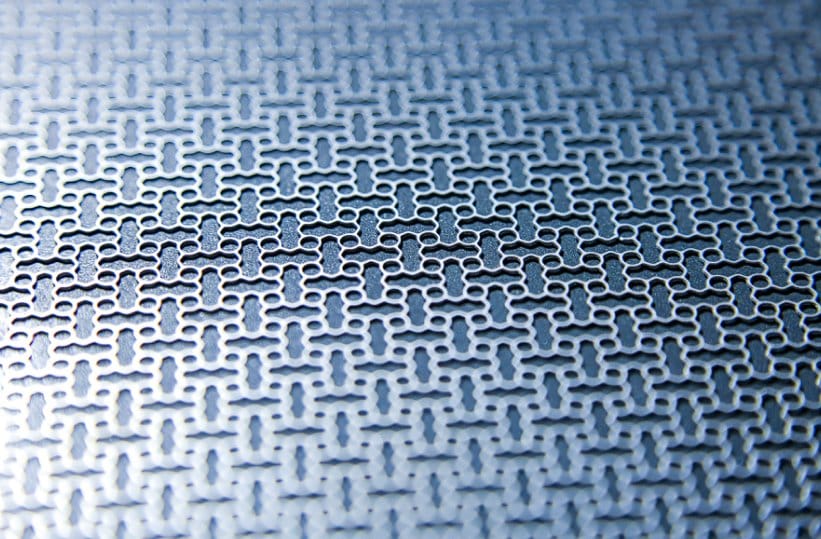

Chemical etching can achieve a minimum standard feature size of 0.075 mm, but apertures smaller than this are possible with development, as is accuracy to less than ±10% metal thickness.

Burr- And Stress-Free Chemical Etching

ACE’s chemical etch process produces parts without burrs or stress, with tolerances that can be as low as 10% of human hair. Our chemical etching process preserves the integrity of the material, even in highly complex designs.

See how it stacks up against CNC machining, laser cutting, and stamping.

When choosing the right manufacturing method, it’s important to weigh precision, flexibility, speed, and cost. The table below highlights how chemical etching compares to other common processes—especially when working with thin, intricate, or sensitive components.

| Precision | ||||

| Tooling Costs | ||||

| Mechanical Stress | ||||

| Design Flexibility | ||||

| Speed | ||||

| Material Compatibility |

Very Short Lead Times

No other manufacturing process can produce stress-free, burr-free metal parts, with the added benefit of being extremely cost-effective with very short lead times.

Over 2000 Metal Types

More than 2000 different metal types and grades are etched by ACE. In addition, we can supply specialist materials on request. We also work with customer supplied metals if required.

Almost Any Metal Etched

The photochemical etching process can profile almost any metal including those considered hard to profile and even some corrosion-resistant metals.

Unfortunately, we are not able to put designs onto finished metal components or shaped metal items.

All of our acid etching is performed utilising perfectly flat sheets of metal.

Please also note that we are only able to chemical etch metal.

Development & Evolution

We are constantly pushing the boundaries of chemical etching, developing new precision processes in our R&D laboratory. Our ongoing innovations make this unique process a competitive engineering solution for virtually every industry.

Scalable Production

arts are supplied clean, burr- and stress-free, with tolerances as precise as 10% of a human hair. The highly repeatable process allows for flexibility—whether producing one-off samples, ramping up production, or manufacturing thousands of parts daily.

High Capability

Tolerances are critical in any design, and with chemical etching, they vary based on material thickness: 0.01 mm – 0.25 mm thick metals: ±0.025 mm standard etch tolerance Above 0.25 mm (up to 2.5 mm): ±10% of metal thickness

Unique Etching Features

ACE can integrate custom design elements into etched products, including logos, barcodes, text, ½-etched fold lines, and surface patterns. We also control etch profiles, enabling conical openings commonly used in filtration meshes to optimize fluid flow.

Opportunities For Growth

ACE is leading the field when it comes to the fast-moving art of developing highly precise etched components. We are constantly evolving and creating innovative chemical etching techniques and delivering precision metal parts, manufacturing millions of etched components per annum in different types of metals and thicknesses to global manufacturing companies across 15 different markets.

Major Industry Partners

The relationship with our customers has been a key part of our success. By partnering with us at every stage of the design and product development process, we can help to achieve the most cost-effective, timely and accurate outcomes to customers’ design and engineering challenges.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.

Unlike other manufacturing processes such as stamping, the cost of chemical etching does not increase with feature complexity. This promotes innovation as designers can, at prototype stage, design multiple parts on a sample photo tool to choose the design best suited for part functionality, rather than use costly hard tooling before the part design is completed. This makes the chemical etching process the ideal choice for both high and low volume production and prototyping.