Bipolar plates a crucial component in the manufacture of fuel cells.

Bipolar plates are used to make connections across the surface of one cathode and the anode of the next cell. Bipolar plates also serve as a means of feeding hydrogen to the anode and oxygen to the cathode.

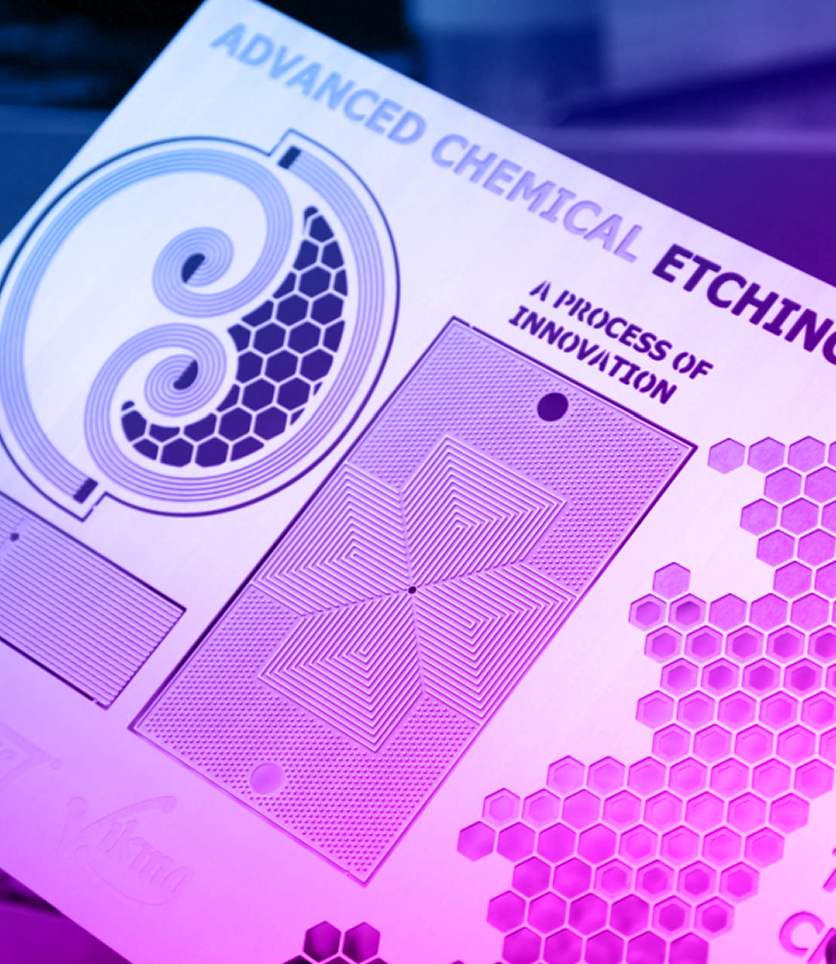

Etching Bipolar Plates: Benefits

Advanced Chemical Etching (ACE) has developed a process of producing plates stress and burr-free at an economical price. Digital tooling, which is low-cost and quick to produce, can be adapted easily and inexpensively to optimise designs. Unlike CNC machining, stamping and hydroforming, chemical etching imparts no mechanical or thermal stress on the plates, which can compromise stack bonding.

Overcoming Design Challenges

The photo etching process removes metal from both sides of the plates simultaneously so complex channels can be etched on both sides of the bipolar plates. Designers can vary the shape and size of channels and incorporate headers, collectors and port features without additional cost. Etched bipolar plates can be produced in a variety of metals including aluminium, titanium, stainless steel and high-temperature nickel alloys.

Whilst CNC machining, stamping and hydroforming can be used to produce channels on bipolar plates, traditional metalworking has limitations, such as compromising planarity (flatness) and introducing stresses and burrs. Single-point machining processes and presswork tooling can also be slow and uneconomical to produce.

The chemical etching process allows bipolar plates to be manufactured in a range of metals, with a range of different flow patterns such as parallel, serpentine, or grid channels, using low-cost photo-tooling and in short turnaround times.

Advanced Chemical Etching can manufacture photochemically etched fuel cell flow plates using aluminium, titanium or stainless steel. The process can be used to produce different prototype designs for the purpose of optimizing the flow pattern. The process can accommodate low, medium or large volume production. Metal plates up to 2 mm in thickness can be etched. The channel width to depth ratio is typically 2:1. Metal plates can be etched from both sides simultaneously.

Bipolar plates are usually made of graphite, metal alloys, or composite materials.

While graphite is lighter than any metal and is not prone to corrosion, it is also brittle and porous and has significantly lower electrical and thermal conductivities compared to metals. Metals, on the other hand, are characterized by very high conductivities. Their corrosion resistance can be enhanced using conductive coatings. For example, titanium is a light metal with very good corrosion resistance which can be further improved by coating the metal with

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.