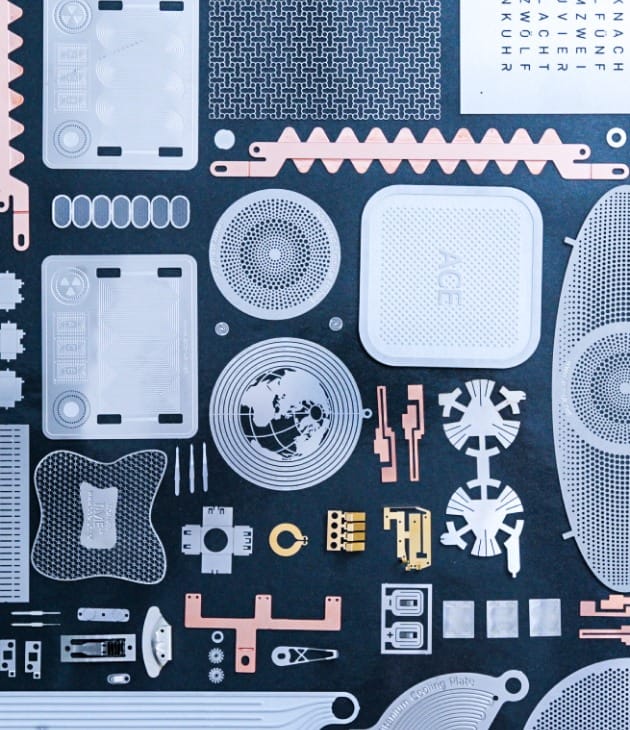

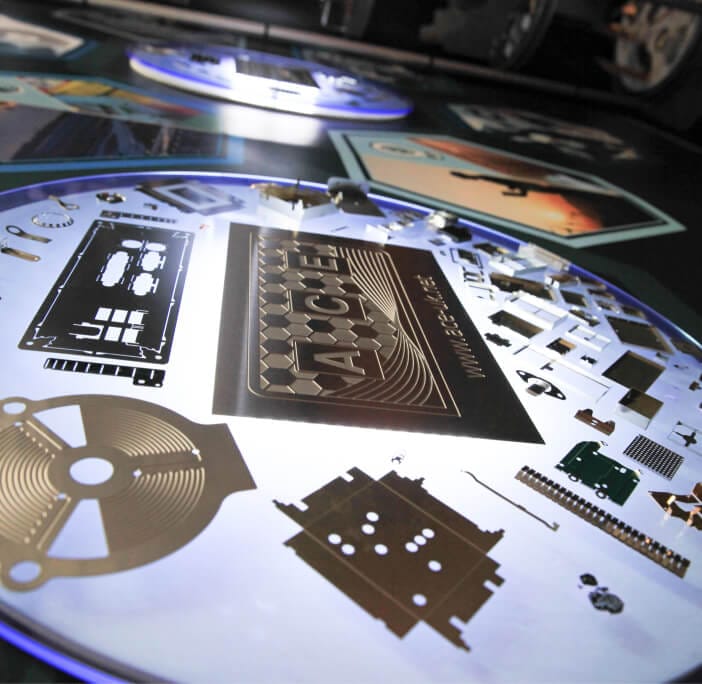

Advanced Chemical Etching’s photo etching process is an economical and flexible method of production. It can produce a wide range of EMI/RFI shielding solutions, from standard shielding/screening cans through to multi-cavity labyrinths, without the associated cost penalty for complexity of the design.

No Limitations

There is no limitation on the complexity of shape; any aperture configuration can be accommodated.

Variety Of Features

The digital tooling is very inexpensive and modifications to tooling can be done very quickly and economically.

Burr & Stress-Free

All parts are burr and stress-free leading to minimum assembly time on the line.

Plating

Parts can be supplied plated for improved solderability, functionality, aesthetics and protection.

Low set-up costs and fast lead times make etching a go-to process in batch sizes of one to multiple millions.

The tooling for etching is digital, low-cost and can be modified quickly.

No heat or force is used when etching so mechanical properties remain unaltered and parts are free from stresses and burrs.

As component features are etched at the same time, part/feature complexity is not an issue.

Flat blanks etched then diffusion bonded or brazed.

No Shape Complexity Limitations

There is no limitation on the complexity of shape; any aperture configuration can be accommodated. Features can be produced such as etched score lines (fold or bend lines) to allow the shields to be stored flat for easy forming by hand or automated using simple tooling.

Special Coatings & Features

The bend lines enable enclosures to be formed with excellent co-planarity. Plimsoll lines can be etched to prevent solder leaching. Special coatings are available to improve the attenuation of high frequencies, selective, dielectric coating enables lower profile cans to be utilised safely.

Total Control Over Quality & Delivery

Very quick delivery from 'agreed design' to supply of finished photo-etched shielding/screening screens can be achieved. Using our in-house forming and spot-welding capability, ACE has total control over quality and delivery.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.