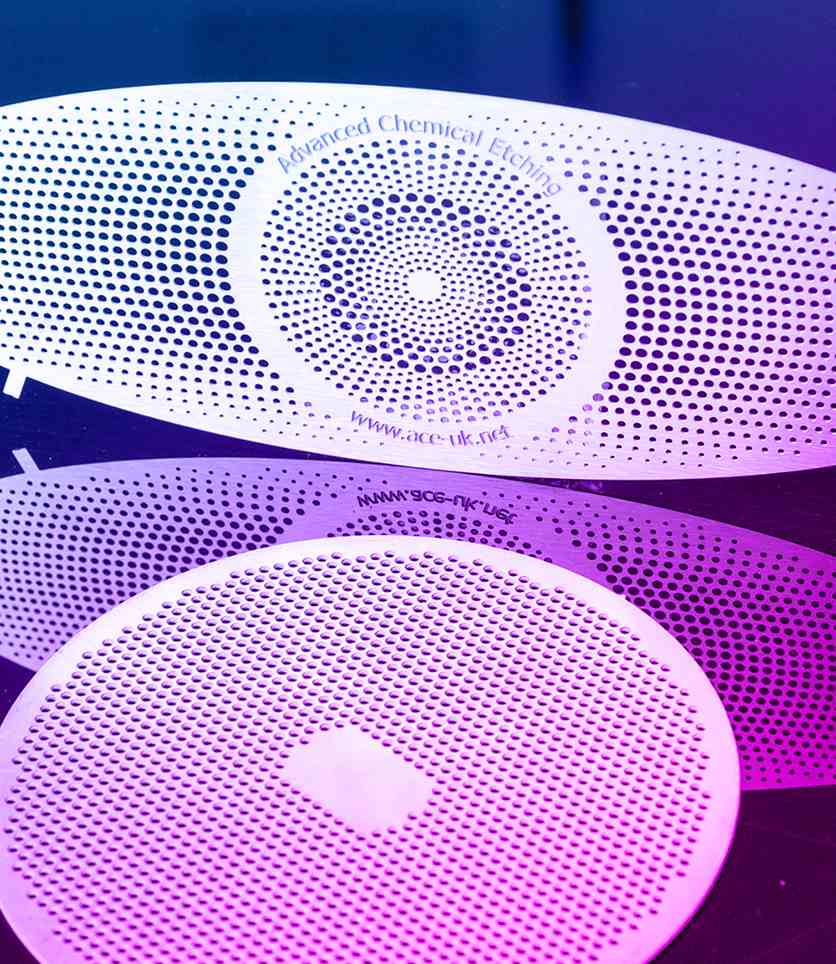

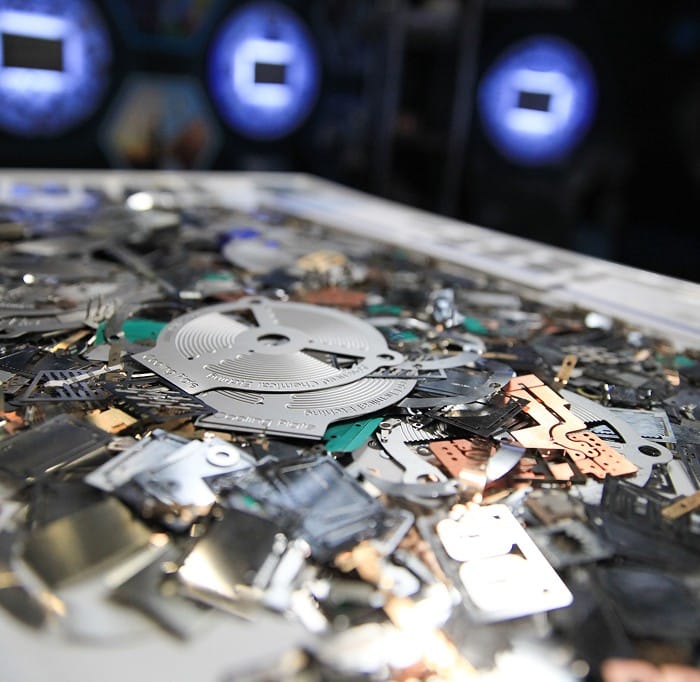

We photo etch simple washers and complex F1 head gaskets to safety-critical aerospace washers, shims, gaskets and titanium shims for the space industry.

Flat Or Assembled

They can be flat, formed or assembled for a variety of technical applications, including aerospace, F1 & precision engineering.

Burr-Free

All are burr-free with no rough edges that could interfere with mating parts.

Digital Tooling

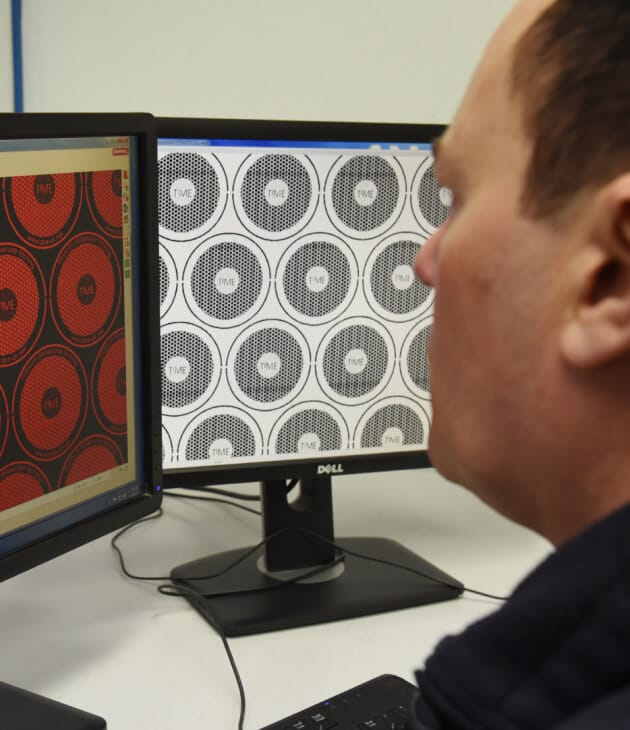

Digital tooling is used to give flexibility in the complexity of the design, lower cost and speedy delivery.

3D Formed Components

3D formed or lipped gaskets can be produced in-house. In addition, a range of surface finishing is available, including electroplating, electropolishing and passivation.

Low set-up costs and fast lead times make chemical etching a go-to process in batch sizes of one to multiple millions.

The tooling for etching is digital, low-cost and can be modified quickly.

No heat or force is used when etching so mechanical properties remain unaltered and parts are free from stresses and burrs.

As component features are etched at the same time, part/feature complexity is not an issue.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.